enEnglish

enEnglish

VIVACOAT® M neo

Ready-to-Use Coating System

Moisture Barrier Coating

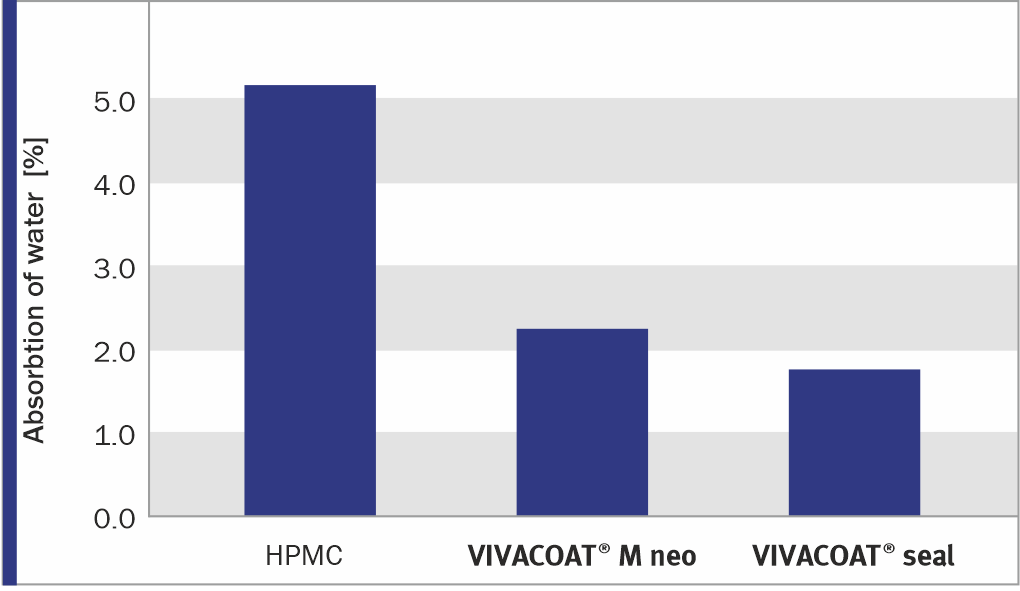

Many APIs are sensitive towards hydrolysis and, thus, humidity lowers the activity of APIs. VIVACOAT® M neo is optimized to protect a moisture sensitive tablet core against humidity.

The best protection can be achieved by the combination of VIVACOAT® M neo and the correct type of protective packaging.

Moisture sensitive tablet cores require advanced knowledge and experience in choosing the best process parameters.

We offer a robust film coating system which shows outstanding performance in both the laboratory and in the production environment.

To get the best out of your equipment you are welcome to use our global technical support. Please refer to VIVACOAT® – technical performance in this brochure.

Recommended Process Parameters

Recon Level [%] | Inlet Temp [°C] | Tablet Bed Temp [°C] | Exhaust Temp. [°C] | Total Spray Rate [g/min] | Pan Speed [rpm] | |

|---|---|---|---|---|---|---|

Fully Perforated Pan, Batch size 800 g | 20 | 67 | 40 - 45 | 44 - 48 | 2 - 3 | 7 - 9 |

Conventional Pan, Batch size 2000 - 3000 g | 20 | n.a. | 42 - 46 | n.a. | 10 - 15 | ca. 5 |

Semi Perforated Pan, Batch size 18 - 20 kg | 20 | 68 | 40 - 45 | 46 - 49 | 55 - 60 | 3 - 4 |

Fully Perforated Pan, Batch size 18 - 20 kg | 20 | 68 | 40 - 45 | 46 - 49 | 60 - 70 | 3 - 4 |

Fully Perforated Pan, Batch size 100 - 120 kg | 20 | 68 | 40 - 45 | 46 - 49 | 180 - 190 | 2 - 3 |

Fully Perforated Pan, Batch size 300 - 400 kg | 20 | 68 | 40 - 45 | 46 - 49 | 700 - 800 | 1 - 2 |

Downloads

Brochure VIVACOAT® M neo Pharma

VIVACOAT® is a robust film coating system which

shows outstanding performance in both laboratory and

production equipment

Brochure VIVACOAT® M neo Nutra

Ready-to-Use Coating System for Nutritional Tablets